-

Old Elk Blended Straight Bourbon Whiskey (750mL)

Regular price $54.95 USDRegular priceUnit price per -

Old Elk 8 Year Old Wheated Bourbon (750mL)

Regular price $109.95 USDRegular priceUnit price per -

Old Elk Four Grain Straight Bourbon (750mL)

Regular price $109.95 USDRegular priceUnit price per -

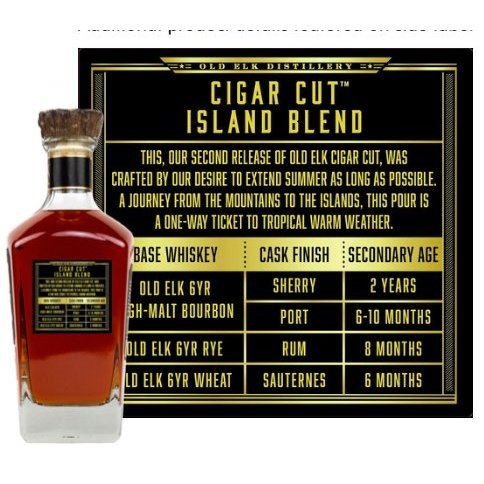

Old Elk Cigar Cut Island Blend Whiskey (750mL)

Regular price $129.95 USDRegular priceUnit price per -

Old Elk Armagnac Cask Finish Bourbon Whiskey (750mL)

Regular price $88.95 USDRegular priceUnit price per -

Old Elk Cognac Cask Finish Bourbon Whiskey (750mL)

Regular price $88.95 USDRegular priceUnit price per -

Old Elk Oloroso Sherry Cask Finish Blended Straight Bourbon Whiskey

Regular price $89.99 USDRegular priceUnit price per -

Old Elk Oloroso Sherry Cask Finish Bourbon Whiskey (750mL)

Regular price $88.95 USDRegular priceUnit price per -

Old Elk 10 Year Old Straight Wheat Whiskey (750mL)

Regular price $126.95 USDRegular priceUnit price per -

Old Elk Infinity Blend Bourbon Whiskey (750mL)

Regular price $164.95 USDRegular priceUnit price per